IT'S TIME FOR A LVL1 MEGA-WORKSHOP!

Sign up now on EventBrite:http://lvl1summercamp2011.eventbrite.com

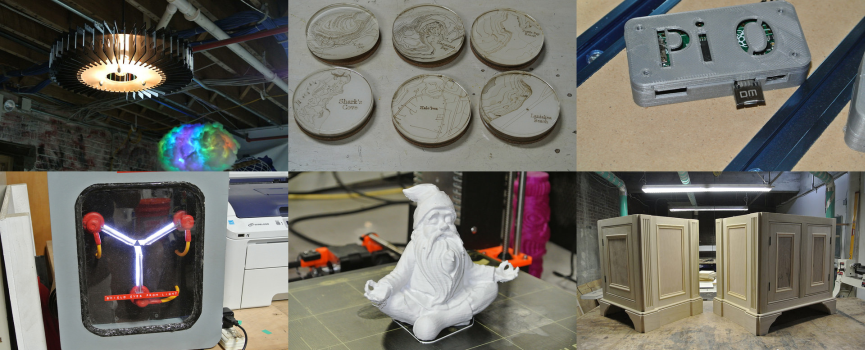

This summer only, at the LVL1 hackerspace in Louisville, KY, you can learn how to Design, Etch, Solder and Program your very own microcontroller project.

This series of four workshops will take place across every Saturday in June, from 1pm to 5pm. Â The first Saturday, you'll learn how to use EagleCAD to route PCBs for manufacture. Â No more perfboard!

The second Saturday, you'll learn how to use dangerous chemicals to turn a blank copper board into a functional AVR programmer!  With this clone of LadyAda's USBTinyISP, you'll be able to program almost ever AtTiny and AtMega chip ever manufactured, freeing you from the surly bonds of the Arduino develoment environment.

The third Saturday, you'll learn extremely useful skills in prototyping with surface mount components, soldering tiny parts on to the boards you etched the week previous.  Surface Mount soldering is  an important skill, as projects and parts get smaller and more powerful.

Finally, on the fourth Saturday, you'll learn how to program a CapsLocker, a nefarious device which masquerades as USB keyboard.  This device is capable of entering any key sequence at any interval, super useful for makinG SURE YOUR MARK ALWAYS TYPES LIKE THIIS.  Or p#erha#ps #ann#o#yin# him# in ##eve#n #mo#r#e interes#ting #ways.

If you want to enroll in all four workshops, purchase the four-pack and the four pack only! Â If you'd like to participate in just the etching and building, purchase the "Etching It and Soldering It" ticket. Â If you'd like to participate in any just the Eagle or Programming workshop, without the fun parts to take home, simply purchase those tickets separately. Â If you're confused, or would like any combination of the above workshops, contact us!

LVL1 members, you get a discount! Contact the appropriate authorities!

Sign up now on EventBrite:http://lvl1summercamp2011.eventbrite.com