Last night I made LVL1's hackerspace passport using our Full Spectrum Engineering laser. It really was not that difficult. I used Chris Cprek's LVL1 logo image for the stamp. It is the Plenary Gear logo at the top left of this page.

I used laserable rubber for this project. Even though it is low-odor you can still smell it. It smells like burning rubber from a car.

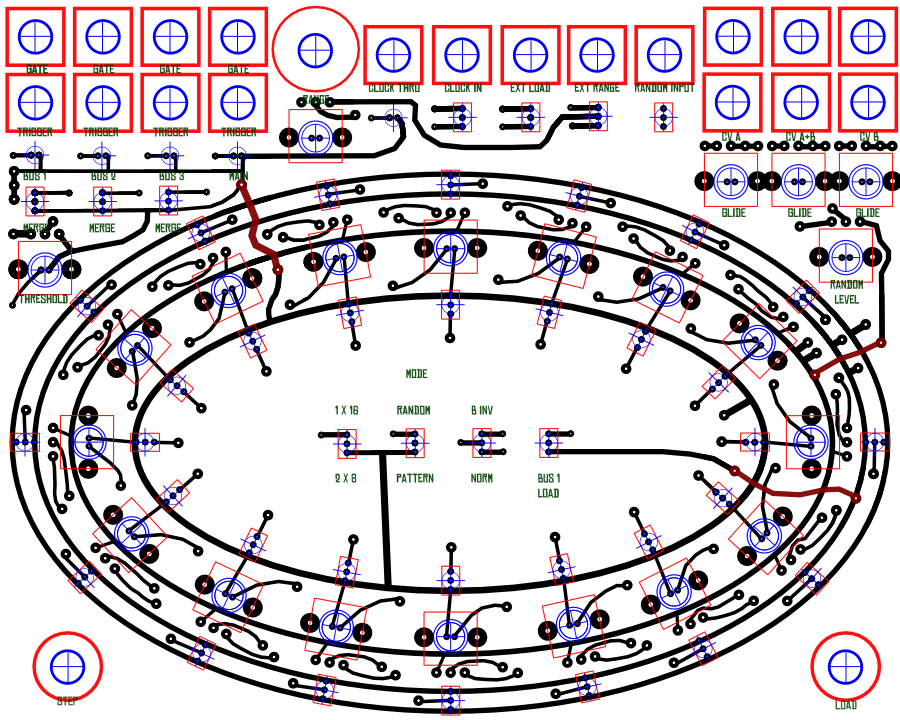

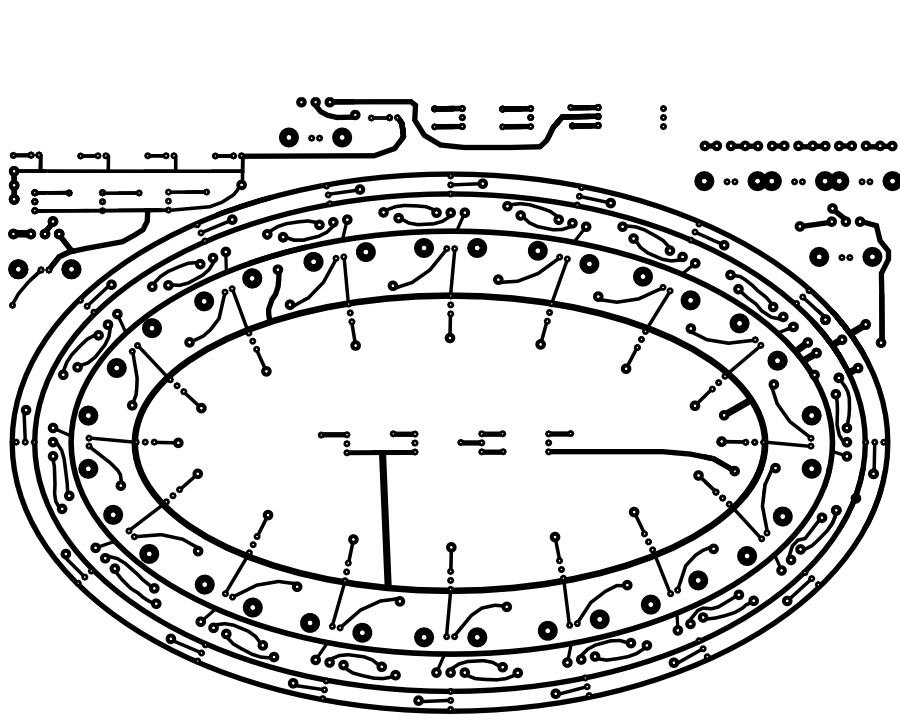

To laser the image, I took the original image and made it black and white. I removed the blue background and cleaned it up a bit using Gimp. I then imported it into Inkscape where I mirrored the image. The letters have to be in mirror image or it will not stamp correctly. Next, I 'printed' to the laser cutter. The Full Spectrum Engineering interface to driving the laser is pretty darned good. If you are reading this post and do not have a laser, check out Full Spectrum, they are a real good value for your money and highly recommended.

For the laser settings, I raster printed the image using 50% speed and 100% power. I tried to cut the rubber around the image, but the rubber does not cut well at all. I tried multiple passes and everything. I ended up using an exact knife.

I also cut a wooden back for the rubber out of some 1/8" baltic birch plywood scrap I had laying around. I used double stick tape to tape the rubber onto the plywood backing. Easy. Finally I hot melt glued a handle onto the stamp. Interestingly, the handle came from the Louisville Slugger Museum and it is a scrap from when a baseball bat is cut out on their lathe.

I used a stamp pad from office depot which worked well and Jon was able to stamp his passport for the first time! I also made another stamp with the Lady Ada graphic from Adafruit. That also came out well.

Today, as I wrote the post, I saw that Becky Stern from AdaFruit posted an excellent 'how to' on stamp making... http://www.adafruit.com/blog/2012/04/03/how-to-laser-cut-your-own-hackerspace-stamp/. It is funny how sometimes you discover someone is doing the exact same thing as you! AdaFruit sells Hackerspace passports if you need one.

Hack on!

Brian